Blog

The Essential Deep Knee Bend

Face it, you can't overlook the Deep Knee Bend (squat) if you want to build impressive muscle size and total body power. This post tells you why this exercise rules supreme.

Build Titanic Triceps with the Dipping Exercise

Looking to build bigger arms with something a bit different? Try the Dipping Exercise described here. It requires no special equipment and builds massive triceps quickly.

Think and Grow Muscles

Learn from the champs, but don't rely on them. This post explains why it is imperative that you think for yourself and become your own training coach if you want to reach your full potential in muscular size and strength.

Greatest Feat of Strength Ever?

What was the greatest demonstration of muscular strength ever exhibited by a human being? The author reflects on an answer to this question expressed by a famous strength writer back in the 1950s.

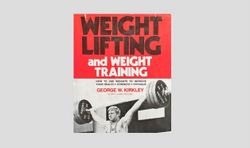

Kirkley on Building Super Leg Strength

Are you struggling to build powerful legs? The squat routine described here might be just what you need. It was advocated by the late George Kirkley, a former Olympic Weightlifting coach and strength-building authority.

Steve Reeves' Favorite Biceps Builder

Learn how Steve Reeves, a former Mr. Universe, built his mighty biceps with the incline dumbbell curl. And, you might be surprised what this exercise can do for you!

Which is the Best Muscle Building Book?

What makes a strength publication valuable, and is there a “best” muscle-building book? Here is a perspective that may shed some light on these two important questions.

A Basement Muscle Builder

Here is a conceptual idea for an easy-to-build power rack & variable-height chinning apparatus for your basement gym. It's bound to be great for doing chin-ups, pull-ups, shrugs, and many other muscle-building exercises.

Looking Back at John Davis, World Champion

John Davis ranks as one of the greatest weightlifters in history. This post takes a look back at his accomplishments as a lifter and his reign as the World's Strongest Man.